Mount DURBAL once and you have no more worries with your application

Mount DURBAL once and you have no more worries with your application

Increasing productivity is a very important argument in many industries.

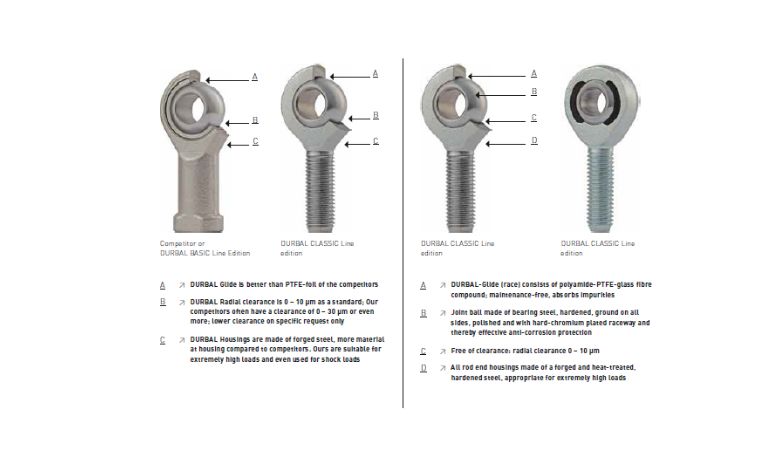

DURBAL offers special solutions with their Classic Line DURBAL-Glide rod ends and spherical plain bearings, they offer a longer wear and very long service life due to the greater thickness of the sliding layer compared to other sliding materials.

Conventional manufacturers on the market offer a thin PTFE film that is inserted or glued into the outer ring of the spherical plain bearing and is destroyed by the slightest foreign object which intrudes and can thus lead to failure of the rod ends and spherical plain bearings. In order to be able to repel this dirt generally, the market competitors are obliged to attach a special sealing solution to their rod ends and spherical plain bearings or they can only offer a version that requires maintenance as an alternative. This must be relubricated at great expense regularly.

DURBAL offers you a clever solution with their injected special plastic (DURBAL-Glide). This has the pleasant secondary property of absorbing foreign bodies and enclosing them harmlessly.

Thanks to many years of experience in this area, DURBAL can reliably manufacture these special features, and special customer requests such as a special torque which is also possible here.

See following rod ends & spherical-plain bearings with DURBAL-Glide technology:

BEF / BEM / EF / EM & GLK / GLE

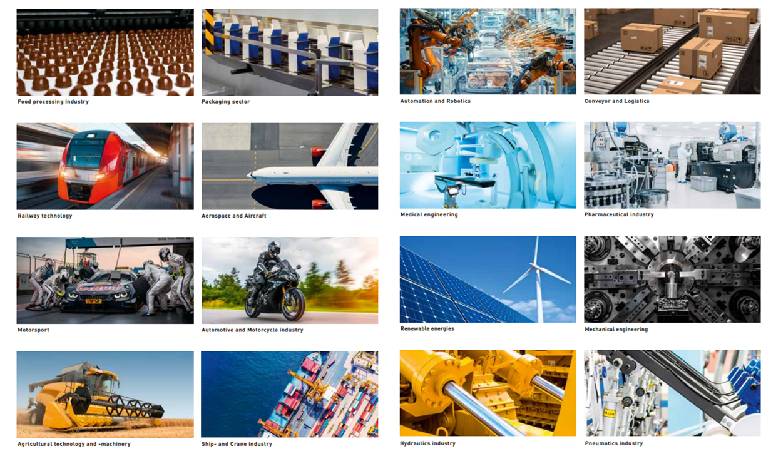

Just explore in which industries you can find DURBAL rod ends & spherical plain bearings!

In addition, they offer customized solutions with their DURBAL heavy-duty linkages.

The high-quality individual components of their heavy-duty linkages are manufactured with high precision and are characterized by their reliability.

If you are interested in such heavy-duty linkages, just fill in this PDF and send it to sales@papadopoulos-sa.com.