Delivering reliable, long-lasting performance.

Based on our know-how and long-standing experience, we are able to offer a range of standard products, as well as optimum solutions for highly specific systems with unique requirements.

Motion Plastics – IGUS

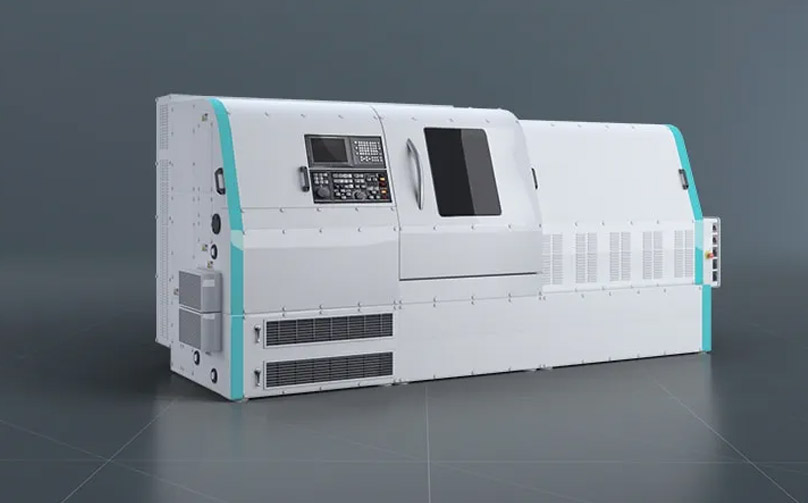

Machines for turning, milling, grinding, or drilling. Machining centres are diverse and often highly specialised. But requirements for suitable igus® products are similar. Reliable energy supply systems, cables, energy-chains, drylin® linear systems & E stepper motors, igus guidelok, slewing ring bearings and iglide plastic plain bearings are always required.

Further to that igus® offers 3D printing service – for individual parts made of high-performance plastics and robot as well for low-cost automation. Just explore the igus® world.

Rolling bearings

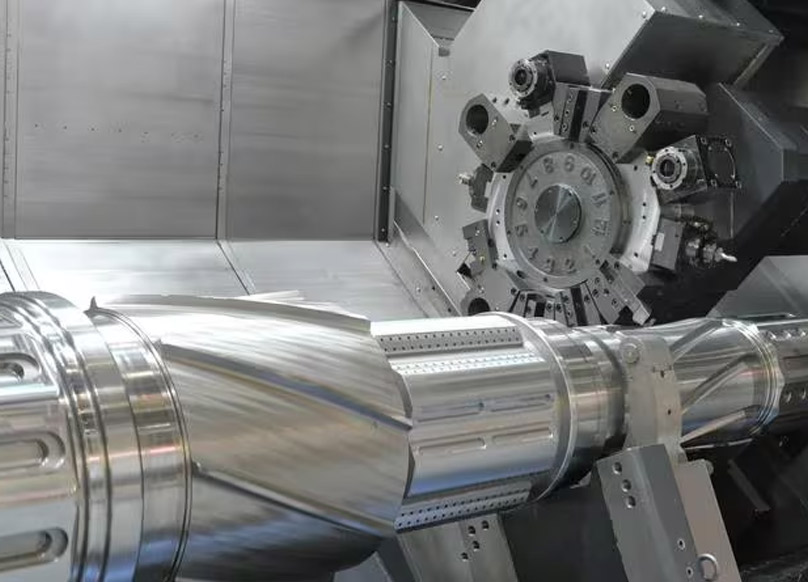

Machine tools are being pushed to the limits to maximize production. At the same time machine operations are becoming more complex. Requirements on higher speeds and faster development results in very high demands on core parts of the machine – especially the spindle units.

With high running accuracy, high-speed performance and high system rigidity, we can offer you super-precision bearings which are ideal for machine tools spindle units. The bearings are designed also to minimize noise, vibration and heat generation.We have a wide assortment of super-precision bearing types, series, designs, variants and sizes – combining the best design for improved performance, machine uptime, speed and precision.

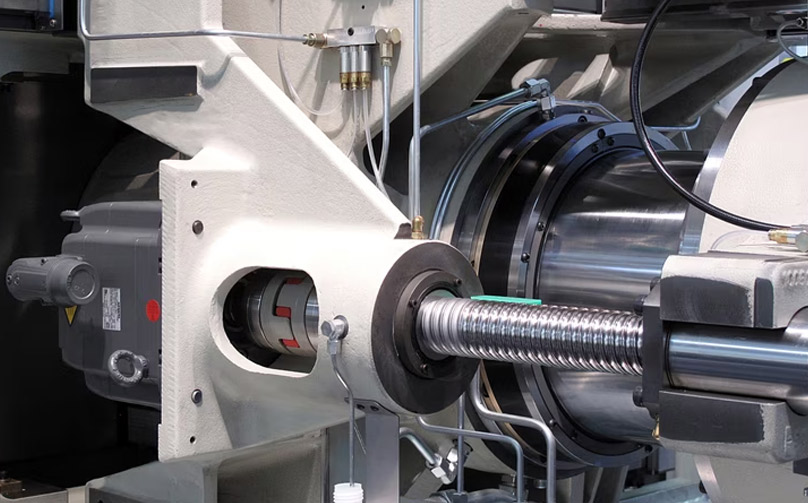

Linear technology

High precision and low noise ball screws for machine tool, automation and high duty applications. Today's automated equipment manufacturers need components and systems that offer high reliability, precision and repeatability with low noise. The new EWELLIX® high performance precision ball screws do this while giving manufacturers a wide range of design flexibility. Further to that we offer a wide range of Linear ball bearings, ball profile guide rails and profile rail bearings. This superior design ensures reliable and friction-free operation of a linear motion system.

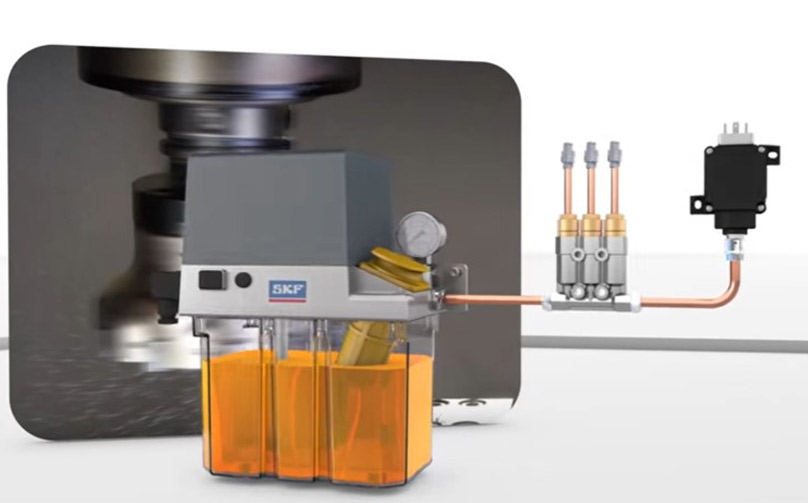

Lubrication systems & Pump systems

Components used in the machinery industry are increasingly designed for continuous loads at the limits of materials and technology. This places extreme demands on lubrication. SKF provide a complete portfolio of lubrication solutions – from manual to automatic lubrication systems for bearings, linear drives and spindles, as well as minimal quantity lubrication for cutting processes and coolant pumps. We also offer fluid pumps for machining processes, and lubrication systems for hydrostatic bedways, chains, presses and assembly processes

Sealing solutions

Machine tools and manufacturing equipment operate continuously in highly demanding environments. Effective sealing is critical to minimize planned maintenance and emergency break downs, while maximizing performance and lowering total cost of ownership. Robust and long-lasting sealing solutions from Trelleborg are therefore required that ensure continuous volume production, at high speed and with precision.

Further to that we can make customized machined seals in minutes instead of waiting days for delivery with our SKF SEAL JET machining system.