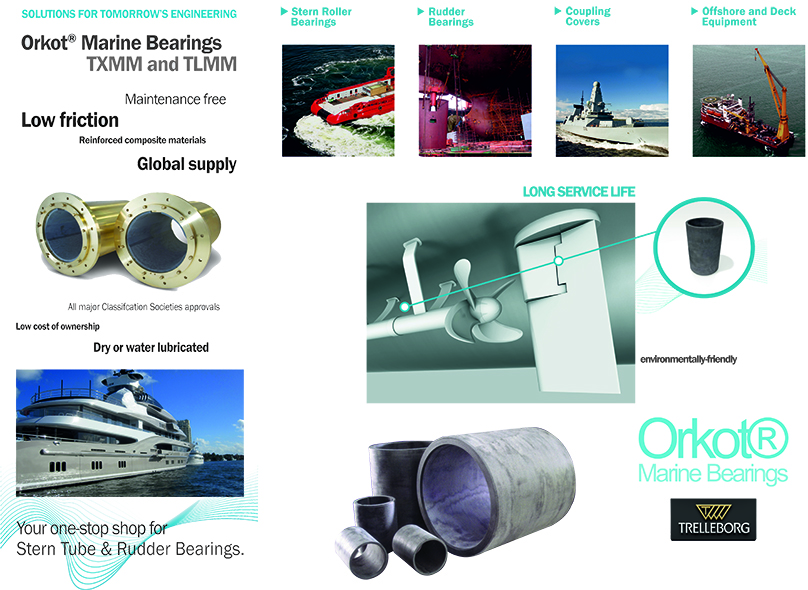

Orkot® Marine Bearings - TLM Marine & TXM Marine

Orkot® Marine Bearings, manufactured and developed by Trelleborg, are the world’s leading composite bearings for the shipping and marine industries.More than 30 years of expertise in marine bearings

Orkot® Marine Bearings are manufactured from a unique synthetic composite incorporating solid lubricants to ensure outstanding wear life.

With virtually no swelling in seawater and a very low thermal coefficient of expansion, the bearings provide dimensional stability in arctic and tropical seas.

In addition, they do not corrode or promote corrosion of the housing and shaft and tolerate both edge loading and misalignment.

Orkot® TLM Marine

Orkot® TLM Marine is an advanced, reinforced polymer material incorporating solid lubricants. The material has exceptional wear resistance and virtually no swell in water, providing dimensional stability. Orkot® TLM Marine tolerates edge loading and misalignment even with the heaviest loads. Orkot® Marine Bearings are installed with an interference fit. Bearings are normally freeze fitted using liquid nitrogen but can be press fitted or resin chocked as required. Where there are extended periods without lubrication, such as upper pintle bearings under light ballast conditions.

Orkot® TXM Marine

Orkot® TXM Marine is an advanced reinforced medium weave polymer material (sometimes called synthetic polymer alloy) using a unique manufacturing process that provides a high concentration of PTFE in the sliding area while maintaining high compressive strength. The PTFE layer is several millimeters thick, making it tolerant to wear, while maintaining its low friction properties throughout the service life of the bearing. The PTFE layer is backed by our well known polymer, Orkot® TLM Marine giving a truly homogeneous bearing material without a metal backing layer. In areas where the running conditions are dry, Orkot® TXM Marine has proved particularly effective in eliminating stick-slip problems normally associated with these operating parameters.

Features

- Ideal replacement for bronze, steel or rubber-linedbushings

- Virtually no swell in water

- High impact strength

- Low coefficient of friction

- High load capacity

- Good chemical resistance

- Operates in fresh or salt water without lubrication

- Damping of vibration

- Accommodation of shaft misalignment

- Ease of machining

- Fitting by pressing, freezing, adhesives and mechanical methods

- Dimensional stability

- Reduced thermal softening and minimal creep

- Does not encourage galvanic corrosion

- Asbestos-free, no environmentally hazardous or toxic substances

Proven Benefits

- Extensive stock available

- Classification approvals

- Low swell in water

- Environmentally friendly

- 24 hour turnaround for non-stock sizes

- Approved dry running capability

- Low coefficient of friction

- Tolerant to edge loading

Applications

- Rudder bearings

- Water lubricated propeller shaft bearings

- Stabilizer bearings

- Weapons handling bearings and guide strips

- Deck machinery bearings

- High strength synthetic rope termination bushings

- Offshore mooring system bearings

- Steering and diving system bearings

- Steering gear bearings

- Stern roller bearings

- Slipway pads

- Sonar bushings and guide strips

- Low magnetic permeability materials for mine counter measure vessels

- Door bushes

- Crane mast bearings