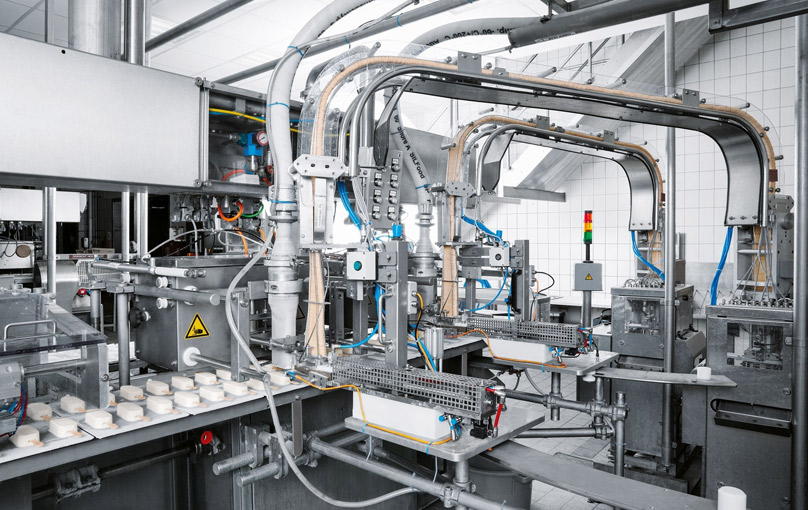

The food and beverage industry has many different processes and functions to reach the final packed end product.

Our wide ranges of products are offering unique advantages to increase performance, optimise processes or save energy at different devices.

Our vast knowledge in the industry supports our clients towards finding the best solution for their applications.

Rolling bearings

A new sealed bearing with food-grade grease. A smart combination of proven technologies for non-corrosive environments, reducing food safety risks and at the same time increasing reliability. Choosing our ball bearing solution for the non-corrosive parts of your production chain also reduces your company's environmental impact. Sealed bearings require no re-lubrication or maintenance and therefore reduce the consumption of grease and grease absorbents. The low friction seal supports reduced energy consumption in the bearings.

Mounted Bearings and Housings

From food grade to food safe

Food grade is commonly considered to be the equivalent of having food-grade seals, food-grade lubricant and corrosion-resistant bearing units. SKF's current generation of bearing units are already food-grade products and are relubrication-free.

However, we are now raising the bar to support pro-active food safety by providing food-safe bearing units that are completely sealed, lubricated for life and designed for increased bearing performance, even in the harshest processing and cleaning environments.

Rod ends, spherical plain bearings

Good taste has always been something special.

Food and beverage should not only taste good, but be healthy. Products from the DURBAL® Premium and Classic Lines are used in the manufacturing of chocolate, ice creams, wine, beer and on fishing trawler fleets with on-board processing facilities.

DURBAL® stainless steel heavy-duty rod ends and spherical plain bearings and other low-maintenance products or items with lifetime lubrication are at your service under extreme external condition, ensuring maximum operational reliability and long machine service lives. With all this, DURBAL® indirectly quenches thirst and satisfies hunger.

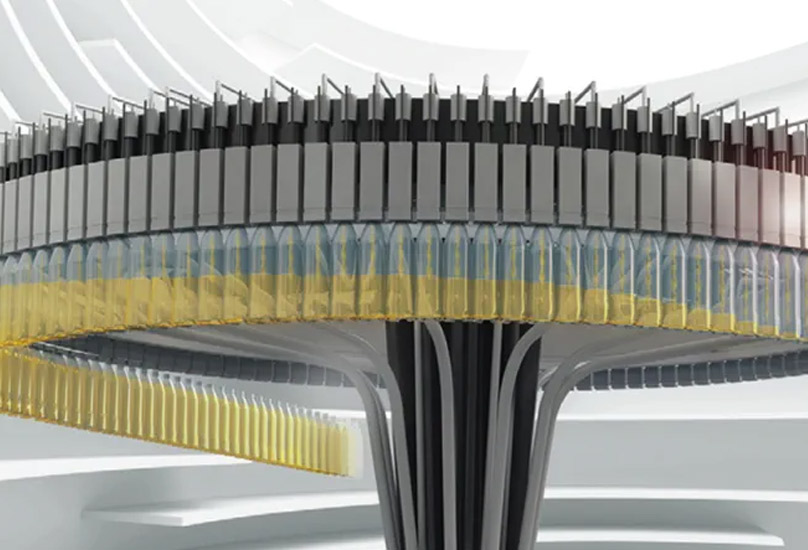

Lubrication systems & Pump systems

Do you know the advantages of automatic lubrication systems and SKF food grade lubricants? The global demand for high-quality and healthy food and beverage is growing every day. As a result, also the requirements on the reliability of machines in F&B industry is increasing. SKF Lincoln lubrication solutions significantly reduce the friction of machine parts. Further to that, selecting the right food grade lubricant for the application can bring multiple benefits: reduced maintenance costs, improved safety and processing efficiency. We have as well the right tools for greasing, mounting and dismounting our products.

Linear technology

Enjoy your espresso coffee with EWELLIX® products. Linear actuators and linear ball bearings for low friction and easy height adjustment of coffee dispensers to fit to the right size of the coffee cup and amount of coffee. This is to avoid splashing at different dispensing heights for increased comfort and ease of use.Further to that, automated flexible filling stations are used when food and beverage liquid has to be brought into bottles and cans. EWELLIX® linear ball bearings and profile rail guides are a perfect solution for precise motion at filling stations. Different stainless steel variants and coatings as well as H1 graded grease options are available on demand.

IGUS Motion Plastics

IGUS offers a wide range of components for hygiene-sensitive areas in the food and beverage industry.

Their high-performance polymers for the food and beverage sector are lubrication-free and can be sterilised with hot steam and cleaned with chemical substances without any problems.

They thus fulfil essential requirements for use in food processing machines and production processes (food safety). The blue colouring also makes them easy to detect.

In addition, they offer all the typical igus advantages such as freedom from maintenance, simple installation and low-noise and low-vibration operation.

Sealing solutions

Trelleborg’s high-performance solutions are engineered to help meet food and beverage compliance and efficiency demands. Sealing solutions in the food and beverage processing industry face a range of challenges. Seals must meet regulatory requirements, while improving productivity. They must be compatible with different food types and ingredients, such as fats, oils and acids. In addition, hygienic design and resistance to cleaning media are top priorities. They offers one of the widest ranges of products and materials specific to the food and beverage processing sector.

Further to that we can make customized machined seals in minutes instead of waiting days for delivery with our SKF SEAL JET machining system.