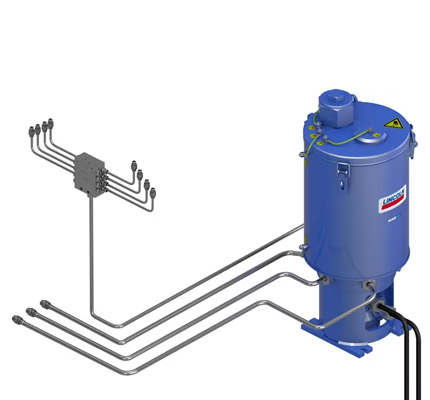

Hydraulically operated pump PFHM-ATEX

Hydraulically operated pump PFHM-ATEX

For use in explosive environments (ATEX) in mining applications

This hydraulically operated, high-pressure multi-line pump comes with one to six pumping elements in five sizes from 0,04 to 0,25 cm³ per stroke or camshaft revolution (0.0024 to 0.0152 in³). The ratio between the hydraulic motor and camshaft is generally 1:1.

The PFHM-ATEX’s sturdy steel housing and reservoir with air breather enable use in dusty areas. When utilized in combination with downstream-located progressive divider valves, it can handle up to approximately 50 lubrication points. The reservoir with stirrer is suitable for both grease and oil and is designed with a locking device.

Features & benefits

- Sturdy design with standard, spring-return pumping elements and ATEX classifications

- Designed for 24/7 operation in harsh environments

- Varying speed and stroke volumes enable economical lubricant settings, hydraulic drive without electrics

- Modular design available in corrosiveness class C3 as standard or C5-M according to DIN EN ISO 12944

- Atex classification for gas, dust and mining application as standard

Applications

- Mining, including underground

- Hydraulically operated machinery

- Screens and crushers in quarries

Catalogues/Downloads

- SKF PFHM lubrication pump for ATEX and mining applications

- SKF Maintenance and Lubrication Products

- SKF Single-line automatic lubrication systems

- SKF Dual-line automatic lubrication system

- SKF Multi-line automatic lubrication systems

- SKF Progressive automatic lubrication systems

- SKF Automatic oil circulation lubrication systems

- SKF Fittings and accessories for lubrication systems

Related products

Εxplore our wide range of products

Rolling Bearings

Mounted bearings and housings

Super-precision bearings

Slewing bearings

Marine Bearings – ORKOT

Maintenance products

Linear technology

Motion Plastics – IGUS

Lubrication systems & Pump systems

Sealing solutions

Power transmission solutions

Rod ends, spherical plain bearings

Couplings

Brake linings

Expansion joints

Shaft braking systems

Motors

Antivibration mountings

Bushings, thrust washers and strips