Multi-line lubrication systems

Multi-line lubrication systems

For demanding applications in nearly all industries

Multi-line pump units supply lubricant to lubrication points without extra metering devices. Thus, each lubrication point has its own pumping element. The system design is simple, accurate and most reliable. Multi-line pumps can be actuated mechanically, electrically or hydraulically.

The easily exchangeable pumping elements are usually operated by eccentric cam. By selecting pumping elements with different piston diameters and/or stroke settings, an individual lubrication volume setting per pump outlet is possible.

Benefits

- Sturdy - durable pump series designed for 24/7 operation

- Simple - continuous lubrication without electrical cycle timers, in most cases

- Versatile - select individual pump element characteristics and oil reservoir size

- Precise - set the required stroke volume at the pumping element

- Broad viscosity range due to special designs and small piston clearance

- ATEX explosion-proof versions available

- Extra, downstream-located low control valves or progressive metering devices possible

Applications

- Vacuum pumps, compressors (all types) and the hyper-compressor industry

- Combustion engines for valve and cylinder liner lubrication

- Important oil total-loss or very small oil circulation applications

- Rubber-mixing machinery, supply of critical plasticizer oil

- Construction and mining machinery

- Tunnel-boring machines

- Forging, bending, forming and cutting presses

- Crushers, cranes and conveyors

- Pumps and compressors

- Rubber-mixing machinery

- Water and slurry pumps

- Meet ATEX and API standards

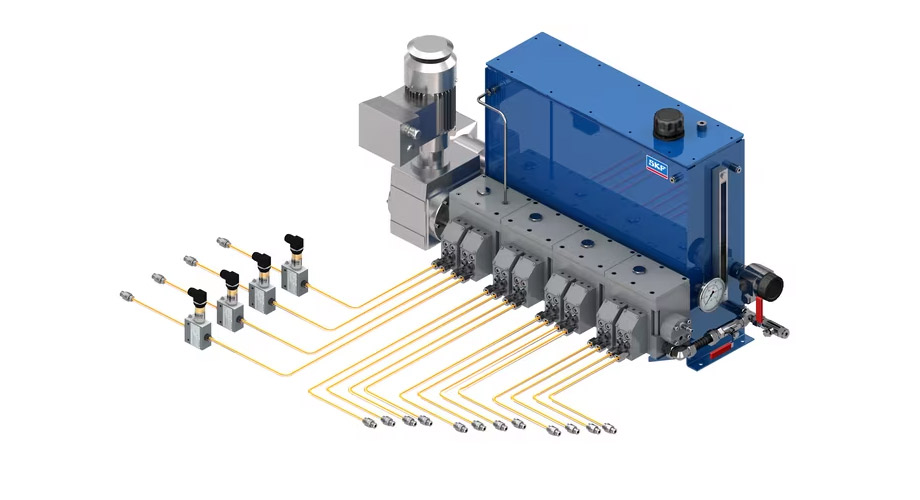

Multi-line lubrication systems for oil

Multi-line oil pumps deliver reliability for high-stressed machines in sensitive areas with extreme vibrations, high back pressures or certain safety regulations.

Description multi-line oil lubrication systems

Multi-line oil lubrication systems consist of the following components: a pump unit, control and monitoring devices, tubing and fittings. Multi-line pump units supply lubricant to lubrication points without extra metering dividers. Thus, each lubrication point has its own pumping element. The system design is simple, accurate and most reliable.

Multi-line pumps can be actuated mechanically, electrically or hydraulically. The easily exchangeable pumping elements are usually operated by eccentric cam. Depending on drive speed, gearbox ratio and selected pump element size, a delivery range from almost 0 to 227 cm3/min (0 to 13,85 in3/min) can be covered. By selecting pumping elements with different piston diameters and/or stroke settings, an individual lubrication volume setting per pump outlet is possible. The potential number of outlets ranges from 1 to 28.

SKF multi-line oil pumps are designed for demanding applications in nearly all industries and for pressure requirements up to 4 000 bar (58 000 psi).

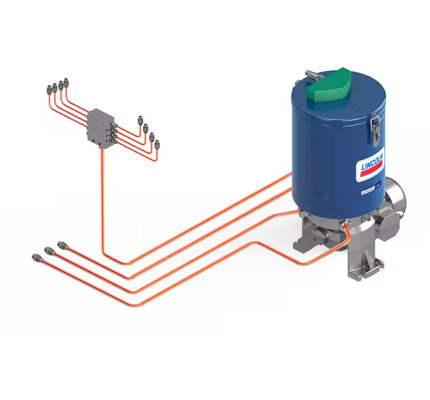

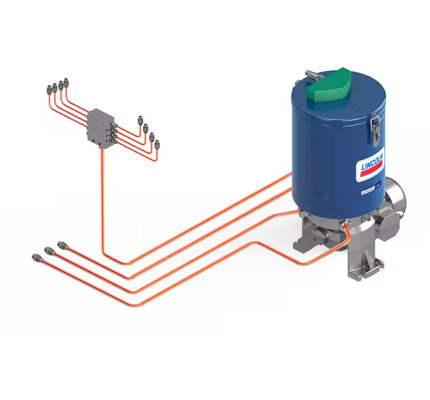

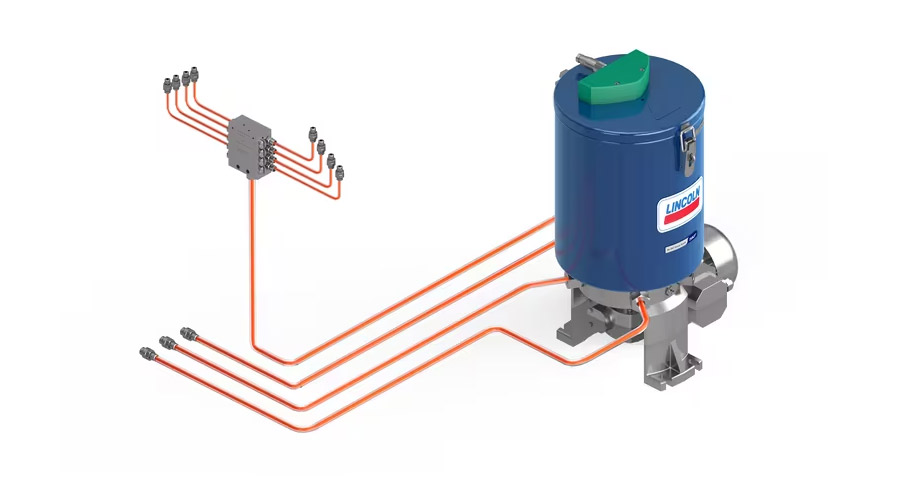

Multi-line lubrication systems for grease up to NLGI 3

Multi-line grease pumps are specified for high-stressed machinery in sensitive and/or dirty areas with pressure requirements up to 350 bar (5800 psi).

Description multi-line grease lubrication systems

Multi-line grease pumps can be actuated mechanically, electrically or hydraulically. The easily exchangeable pumping elements are usually operated by eccentric cam. Depending on the drive speed, gearbox ratio and selected pump element size, a delivery range from almost 0 to 35 cm3/min (0 to 2.13 in3/min) can be covered. The built-in stirrer mixes the grease (grease softening process), is synchronized with the pump element suction stroke, and assists the heavy lubricant to low into the suction chamber. This unique concept supplies heavy lubricants usually up to NLGI 3.

An individual lubrication volume setting per pump outlet is possible by selecting pumping elements with different piston diameters and/or stroke settings. The potential numbers of outlets range from 1 to 30. SKF multi-line grease pumps are designed for demanding applications in nearly all industries. Most pump versions are available with special reservoirs for oil. The P 215 and P 230 pump series enable the use of plasticizer oil for the rubber industry.

Catalogues/Downloads

- SKF Dual-line automatic lubrication systems

- SKF Automatic Lubricators

- SKF Maintenance and Lubrication Products

- SKF Single-line automatic lubrication systems

- SKF Dual-line automatic lubrication system

- SKF Multi-line automatic lubrication systems

- SKF Progressive automatic lubrication systems

- SKF Automatic oil circulation lubrication systems

- SKF Fittings and accessories for lubrication systems

Related products

Εxplore our wide range of products

Rolling Bearings

Mounted bearings and housings

Super-precision bearings

Slewing bearings

Marine Bearings – ORKOT

Maintenance products

Linear technology

Motion Plastics – IGUS

Lubrication systems & Pump systems

Sealing solutions

Power transmission solutions

Rod ends, spherical plain bearings

Couplings

Brake linings

Expansion joints

Shaft braking systems

Motors

Antivibration mountings

Bushings, thrust washers and strips