A Champion in Food Safety

A Champion in Food Safety

A Champion in Food Safety

We all trust that the food and beverages we consume are safe and of high quality. In truth, most people rarely think about food safety – and that’s because of you. As key players in the industry, you ensure that food safety is always a priority. You are the quiet champions, safeguarding the well-being of billions around the globe.

But even champions need strong partners – and we’re here to support you. Meet a true ally in our Food Line portfolio: our hygienically designed ball bearing units.

Hygienic Design – Vital for Food Safety

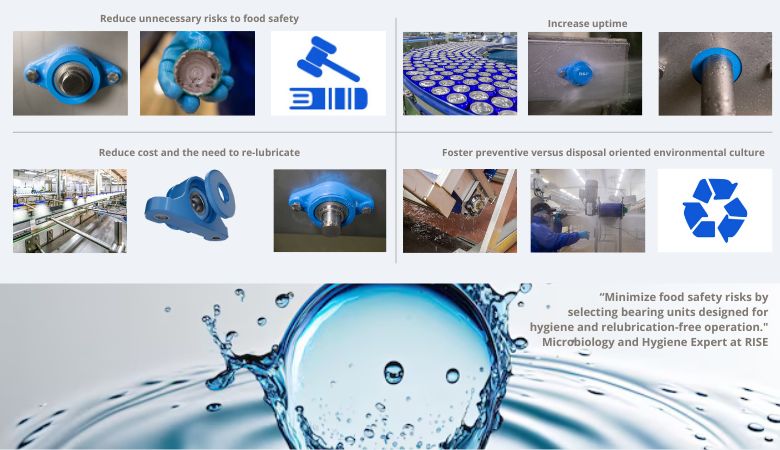

Hygienic design plays a crucial role in preventing product recalls and meeting regulatory requirements.

SKF Food Line ball bearing units

are meticulously engineered, from each component to the entire system, to enhance cleanliness during washdowns, safeguard your products, and ensure regulatory compliance.

SKF Food Line Ball Bearing Units

From Food Grade to Food Safe

Food grade typically refers to products with food-grade seals, lubricants, and corrosion-resistant bearing units.

SKF’s latest generation of bearing units already meet these standards and are relubrication-free.

Now, we are taking it a step further by introducing food-safe bearing units.

These units are fully sealed, lubricated for life, and designed to deliver enhanced performance, even in the most demanding processing and cleaning conditions, ensuring proactive food safety.

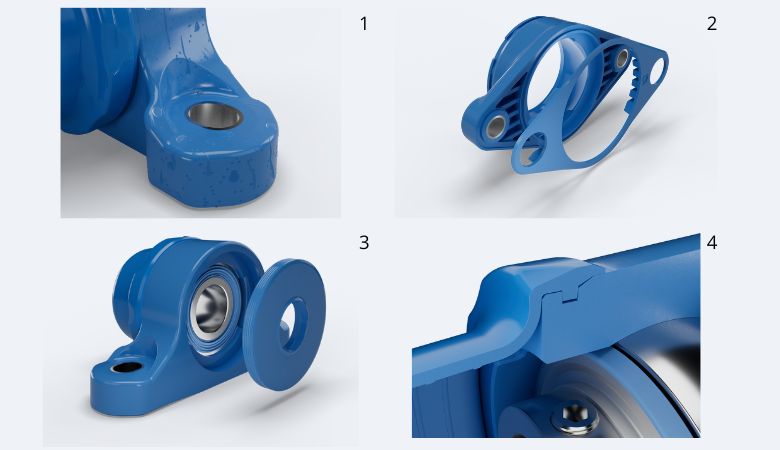

The hygienic geometry (1)

of the housings reduces the possibility of contaminant traps.

The insert bearing made of food grade rubber is over-moulded with the composite housing to form an effective base seal (2)

against the mounting frame.

The back seal prevents (3)

contaminants from entering the bearing cavity by sealing statically against the housing and dynamically against the shaft.

The end cover (4)

forms an effective interference seal with the housing and incorporates positive locking to prevent dislodging.

Just watch this video: SKF - the innovation behind SKF food line ball bearing units

The Innovation Story

Watch the a.m. video to discover the story behind this innovation.

Learn about the gutter-inspired sealing system and how the SKF development team set a new standard for hygienic design in bearing units.

Lower Maintenance and Related Costs

The blue line SKF ball bearing units

are designed for relubrication-free operation and enhanced performance, even in tough environments, helping you reduce maintenance expenses.

For instance, re-lubricating 100 bearing positions weekly requires 70 kg of lubricant per year, not to mention the labor involved.

33% Less Water Usage, Energy Savings, and Waste Reduction With hygienically designed open bearings, you can achieve environmental benefits,

such as using 33% less water for cleaning compared to standard relubricable units, while also eliminating the need for grease absorbents disposal.

Estimate your cost of bearing re-lubrication or your environmental cost and impact,

just ask our SKF food line expert team how we can support you or download the SKF food line ball bearing units catalogue here