Tapered Roller Bearings

Tapered Roller Bearings

With a wide range of designs to choose from, tapered roller bearings are also customizable to match your specific speed, load, contamination, temperature or vibration conditions.

The Tapered roller bearings feature a cup and cone assembly. The cup is comprised of the outer ring and the cone assembly consists of inner ring, rollers, and cage.

This bearing construction accommodates combined loads and provides low friction during operation. By adjusting one single row tapered roller bearing against a second tapered roller bearing and applying a preload, a rigid bearing application can be achieved.

Explorer deep groove ball bearings – meeting demands beyond standard

More robust than typical deep groove ball bearings, they are highly customizable with the possible combination of many different components. This results in up to 10 000 possible configurations! Find the optimum configuration to deliver the kind of high performance you need – whether that’s exceptional durability, for example, or lower friction.

Quiet Running deep groove ball bearings

Designed especially for wind turbine generators, SKF Quiet Running deep groove ball bearings significantly reduce noise levels and structural resonance. They are less sensitive to variable operating conditions, can increase bearing service life and extend relubrication intervals.

Applications

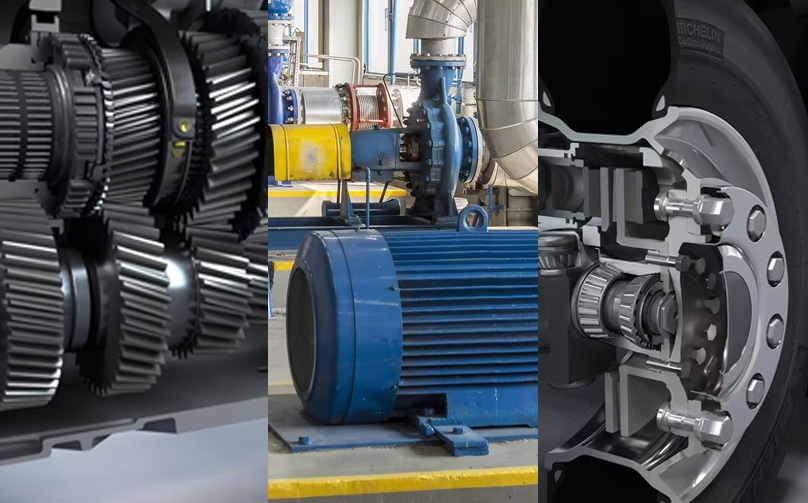

Single row tapered roller bearings are typically used in applications with combined loads.

Single row tapered roller bearings can also be used in sets. Single row tapered roller bearings can be matched face-to-face, back-to-back or in tandem to deliver specific advantages depending on operating conditions.

Double row tapered roller bearings are typically used in gearboxes, hoisting equipment, rolling mills and machines in the mining industry.

Four row tapered roller bearings are used almost exclusively in work roll applications

such as rolling mills.

Special variants

In addition to the bearings presented in this section, SKF supplies tapered roller bearings for special application requirements including:

- Bearings with Solid Oil

- INSOCOAT bearings

- NoWear coated bearings

- Hub units for industrial, automotive, railway and off-highway applications

On request, SKF can also supply customized tapered roller bearings for various operating conditions to meet the customer and application requirements.

Special variants

Catalogues/Downloads

Catalogues/Downloads

Εxplore our wide range of products

Rolling Bearings

Mounted bearings and housings

Super-precision bearings

Slewing bearings

Marine Bearings – ORKOT

Maintenance products & tools

Linear technology

Motion Plastics – IGUS

Lubrication systems & Pump systems

Sealing solutions

Power transmission solutions

Rod ends, spherical plain bearings

Couplings

Brake linings

Expansion joints

Shaft braking systems

Motors

Antivibration mountings

Bushings, thrust washers and strips