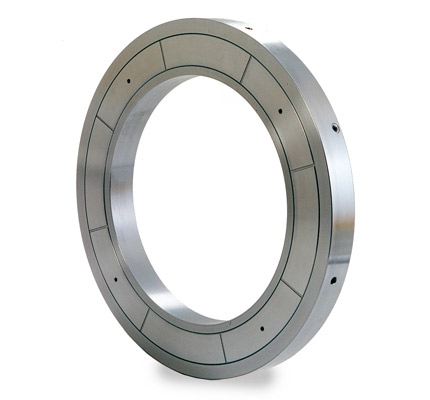

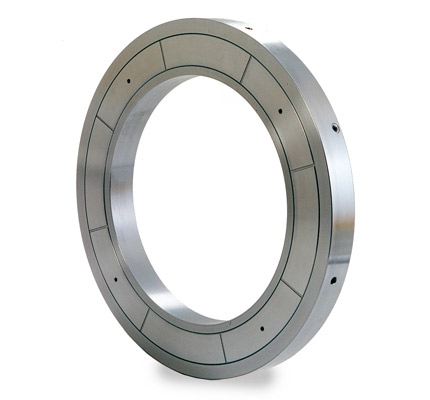

Rings and nuts

Rings and nuts

Hydraulic rings and propeller nuts, a time saving technology from SKF. The time saving technology from SKF. Traditionally, ship propellers are mounted on a tapered shaft end with a nut and key. The torque is transmitted through friction of the mating surfaces and the key performs a stand-by function if the friction is insufficient.

On mounting, the propeller is driven up the taper by heating the propeller hub and driving in keys between the nut and the hub, or by using a hydraulic press or even flogging the nut to achieve the required axial drive up.

All these methods are time consuming and difficult to manage due to the large forces required. For large propellers the methods are unacceptable. These conventional methods are especially troublesome when dismounting propellers from shafts. Withdrawal forces are large and fretting damage often occurs on the contact surfaces. Due to the large forces, withdrawal tools are often bulky, expensive and difficult to handle. The dismounting process is therefore very time consuming.

The SKF oil injection method combined with a hydraulic ring or nut from SKF solves all these problems and simultaneously eliminates the use of keys and keyways. This method is fully accepted by all the worlds leading classification societies and hundreds of references for all types of vessels are available.

Catalogues/Downloads

Εxplore our wide range of products

Rolling Bearings

Mounted bearings and housings

Super-precision bearings

Slewing bearings

Marine Bearings – ORKOT

Maintenance products

Linear technology

Motion Plastics – IGUS

Lubrication systems & Pump systems

Sealing solutions

Power transmission solutions

Rod ends, spherical plain bearings

Couplings

Brake linings

Expansion joints

Shaft braking systems

Motors

Antivibration mountings

Bushings, thrust washers and strips