Progressive lubrication systems

Progressive lubrication systems

For small- to medium-sized machines that require continuous lubrication

Progressive systems provide continuous lubrication as long as the pump is in operation. Once the pump stops, the pistons of the progressive metering device will stop in their current positions. When the pump starts supplying lubricant again, the pistons will carry on where they left. Therefore, the progressive circuit of one outlet of the pump will stop when only one lubrication point is blocked. The blockage serves as a means of control and forces personnel to service the system.

Only one outlet of a primary or a secondary metering device of one pump outlet can be monitored visually or electrically, depending on the chosen metering device.

Benefits

- Continuous lubrication - Delivers frequent and measured amounts of lubricant to each lubrication point

- Reliable monitoring and control - Easy system monitoring and simple blockage control, integrated system control and monitoring

- Effective in harsh conditions - Potentially high lubrication point back pressure, dirty, wet or humid environments (including ATEX / EEX), and low temperatures

Applications

- Construction machines (concrete pumps, mortar pumps, loaders, excavators, trenchers)

- On-road trucks (snow removal, waste press)

- Agricultural machines (harvesters, balers, manure spreaders, sugar cane loaders)

- Wood reclaimers

- Material handling (reach stackers, crane carts)

- Asphalt mixing plants

- Wind turbine generators

- Food and beverage facilities (fillers, washing machines)

- Oil and gas industry reciprocating compressors

Description

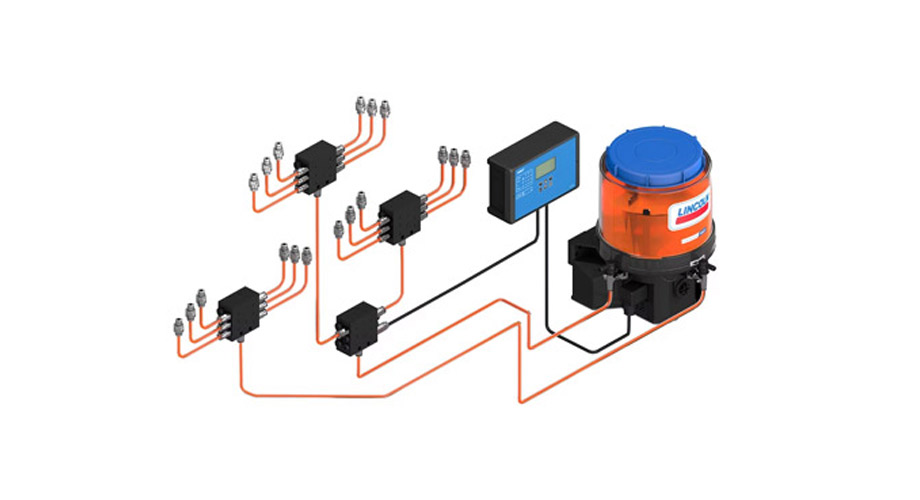

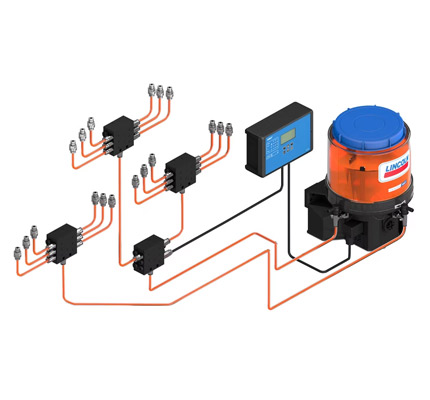

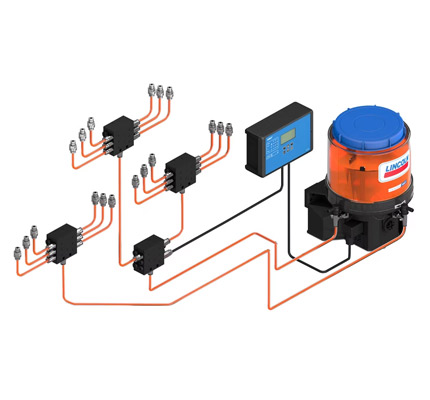

Progressive systems, SKF ProFlex and Lincoln Quicklub, can be used on small- to medium sized machines with dispersed lubrication points that require varying lubrication quantities.

Progressive lubrication systems consist of a pump connected to at least one primary metering device. If needed, second level metering devices can be connected to the outlets of the primary metering device to increase the number of lubricated points. The outlets of the primary and second level metering devices are connected via branch lines to the lubrication points of the machine. A third level of metering devices is not recommended. The pump supplies lubricant to the metering devices with pressure up to 550 bar (8 000 psi), depending on the pump model.

The metering devices split the lubricant into even or predefined amounts of lubricant. The lubricant amount provided by each outlet of the metering device depends on the type of metering device being used.

Progressive systems can dispense a precise, metered amount of lubricant to up to 150 lubrication points over distances of approximately 15 m (16 yd).

Catalogues/Downloads

- SKF Dual-line automatic lubrication systems

- SKF Automatic Lubricators

- SKF Maintenance and Lubrication Products

- SKF Single-line automatic lubrication systems

- SKF Dual-line automatic lubrication system

- SKF Multi-line automatic lubrication systems

- SKF Progressive automatic lubrication systems

- SKF Automatic oil circulation lubrication systems

- SKF Fittings and accessories for lubrication systems

Related products

Εxplore our wide range of products

Rolling Bearings

Mounted bearings and housings

Super-precision bearings

Slewing bearings

Marine Bearings – ORKOT

Maintenance products

Linear technology

Motion Plastics – IGUS

Lubrication systems & Pump systems

Sealing solutions

Power transmission solutions

Rod ends, spherical plain bearings

Couplings

Brake linings

Expansion joints

Shaft braking systems

Motors

Antivibration mountings

Bushings, thrust washers and strips