Oil and air lubrication units

Oil and air lubrication units

Oil and air lubrication units

A flow of air inside a narrow tube teases a droplet of oil apart to form streaks that are then transported to the lubrication point. A nozzle continually supplies the bearing with oil in the form of fine droplets. The transporting air stream is practically oil-free upon leaving the bearing.

The components can be supplied as a complete unit (model OLA) or individually. Purchasing individual components makes sense if the lubrication system is not going to be installed on the machine as a complete unit (e.g. for reasons of space).

Different criteria

- Better machining performance in spindle bearing lubrication due to higher speed factors

- Higher dependability due to continuous supply of defined quantities of lubricant; sealing air provided by the system protects the bearings against outside contamination

- Less lubricant usage – as much as needed, as little as possible – for greater safety and environmental protection

- Demand-based metering for each lubrication point, with approximately 90% lower lubricant consumption compared to oil lubrication;

- No oil mist, no repack period compared to grease lubrication

Applications

- Bearing lubrication, especially of spindle bearings

- Chain lubrication

- Gear train lubrication

- Slideway lubrication

- Assembly and process oiling

Catalogues/Downloads

- SKF and Lincoln automatic lubrication systems

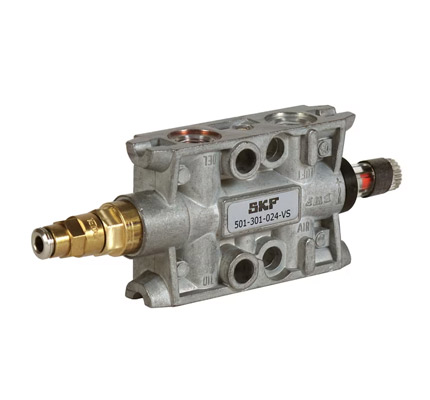

- SKF Oil+Air Lubrication Units and Mixing Valves – Product Series OLA, MV and 161span class=”icon-link icon-title”>

- SKF Maintenance and Lubrication Products

- SKF Single-line automatic lubrication systems

- SKF Dual-line automatic lubrication system

- SKF Multi-line automatic lubrication systems

- SKF Progressive automatic lubrication systems

- SKF Automatic oil circulation lubrication systems

- SKF Fittings and accessories for lubrication systems

Εxplore our wide range of products

Rolling Bearings

Mounted bearings and housings

Super-precision bearings

Slewing bearings

Marine Bearings – ORKOT

Maintenance products

Linear technology

Motion Plastics – IGUS

Lubrication systems & Pump systems

Sealing solutions

Power transmission solutions

Rod ends, spherical plain bearings

Couplings

Brake linings

Expansion joints

Shaft braking systems

Motors

Antivibration mountings

Bushings, thrust washers and strips