Oil and air lubrication systems

Oil and air lubrication systems

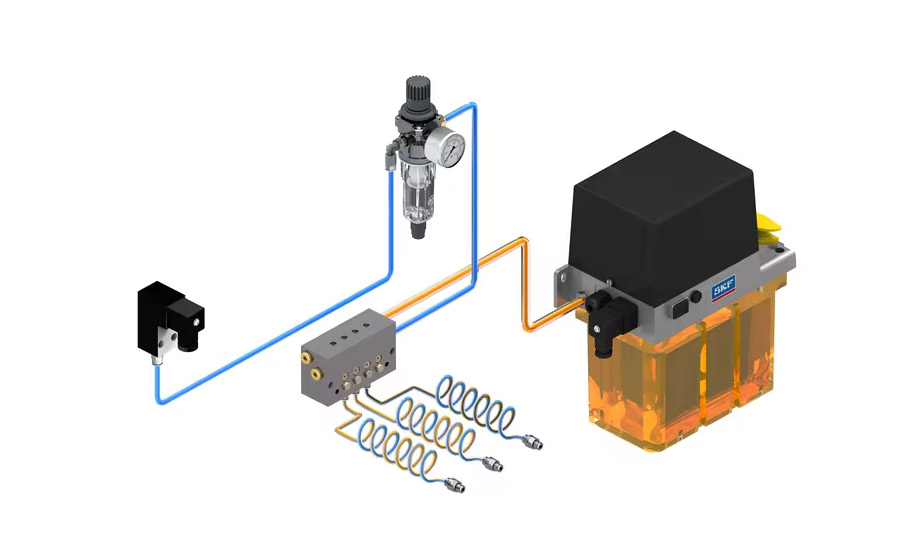

A drop of oil is pulled apart in streaks by a current of air in a narrow tube. It is then transported in the direction of the lube point. The bearing is continuously supplied with fine droplets of oil from the outlet nozzle. The carrier air leaves the bearing nearly free of oil.

Oil and air lubrication systems can be tailor-made and apply leading oil-streak sensor technology.

Features & benefits

- Prevent abrasion and skidding

- Protect surfaces from corrosion

- Protect the contact area from particle contamination

- Better machining performance

- Higher dependability

- Less lubricant consumption

Typical applications

- High speed bearings in machine tool spindles

- Chains

- Special applications in the steel industry

Oil and air lubrication systems

For high-speed spindle bearings, chains and special applications in the steel industry.

In oil and air lubrication systems, a volumetrically metered quantity of oil is pulled apart by a continuous air flow in a tube. It is carried along the tube wall in the direction of compressed-air flow. The quantity of oil is fed into the air flow in pulses at a mixing point (mixing valve). A nearly continuous flow of oil is produced that leaves the outlet nozzle as fine drops and is fed to the rolling bearing without contact. This means that the bearing housing is under a slight overpressure, which keeps dirt away from the sensitive bearings.

The carrier air leaves the bearing nearly free of oil. This concept creates no oil mist or oil fog, making it environmentally friendly as well.

Εxplore our wide range of products

Rolling Bearings

Mounted bearings and housings

Super-precision bearings

Slewing bearings

Marine Bearings – ORKOT

Maintenance products

Linear technology

Motion Plastics – IGUS

Lubrication systems & Pump systems

Sealing solutions

Power transmission solutions

Rod ends, spherical plain bearings

Couplings

Brake linings

Expansion joints

Shaft braking systems

Motors

Antivibration mountings

Bushings, thrust washers and strips