LubriLean DigitalSuper

LubriLean DigitalSuper

LubriLean DigitalSuper

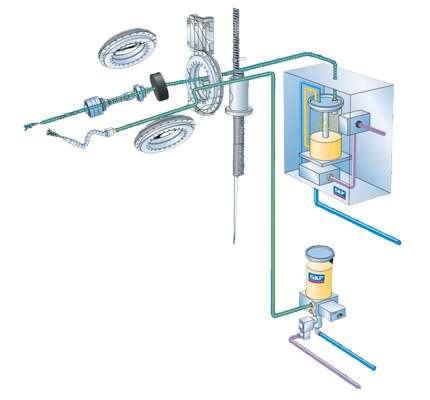

Units for internal and external Minimal Quantity Lubrication (MQL)

The innovative technology of the SKF LubriLean DigitalSuper makes it possible to use minimal quantity lubrication (MQL) for a wide range of cutting applications.

The unit’s innovative generation of aerosol, combined with a powerful integrated control unit, constantly provides an optimal supply of oil for the cutting process. Even in case of unfavourable pressure ratios caused by the application (deep-hole drilling) or by small diameter cooling ducts. The LubriLean DigitalSuper stands out due to its performance as well as for its very user-friendly operation.

SKF LubriLean can replace the centralized cooling system in many machining processes. It assists customers in reducing costs of cooling system operation and maintenance, enables higher metal-cutting speed, increases the machining surface quality, extends the tool’s service life and lowers the passive impact on the environment.

A PROFIBUS or PROFINET interface conforming to HPC specifications permits easy system integration.

The active Bypass-Control (BPC) has been developed for advanced drilling tasks such as deep-hole drilling with small tool diameters (<5 mm).

Features & benefits

- Usable in nearly all production processes (optimally defined droplet size of 0,5 μm)

- Short response times (tool changes)

- No moving parts (thus wear-free)

- Specially suitable for small tools and high cutting speeds

- Simple integration in machine tool systems (retrofits, standard)

- Aerosol transport through lines as long as 20 m

- Continuous and homogeneous aerosol flow

- No energy consumption for aerosol production

Applications

- Machine tools

- General industry

- Metal and plastic forming machinery

Catalogues/Downloads

- SKF Product series DigitalSuper

- SKF LubriLean Minimal quantity lubrication improves ecological and economic efficiency

- SKF Maintenance and Lubrication Products

- SKF Single-line automatic lubrication systems

- SKF Dual-line automatic lubrication system

- SKF Multi-line automatic lubrication systems

- SKF Progressive automatic lubrication systems

- SKF Automatic oil circulation lubrication systems

- SKF Fittings and accessories for lubrication systems

Related products

Εxplore our wide range of products

Rolling Bearings

Mounted bearings and housings

Super-precision bearings

Slewing bearings

Marine Bearings – ORKOT

Maintenance products

Linear technology

Motion Plastics – IGUS

Lubrication systems & Pump systems

Sealing solutions

Power transmission solutions

Rod ends, spherical plain bearings

Couplings

Brake linings

Expansion joints

Shaft braking systems

Motors

Antivibration mountings

Bushings, thrust washers and strips