J. & E. Papadopoulos SA is since many years an authorized distributor of BREMSKERL® in Greece.

BREMSKERL - Friction lining manufacturer since 1929

BREMSKERL-REIBBELAGWERKE EMMERLING GmbH & Co. KG is a family owned globally active SME whose head office is in Estorf-Leeseringen, near Nienburg an der Weser.

With 350 employees globally, 300 of whom work in Germany alone, they develop and manufacture class certified brake linings for marine anchor windlass, anchors, winches, deck machinery, as well as for offshore and industrial applications.

Together with their worldwide subsidiaries in North America, Great Britain, China and India they are internationally known.

Rapid and direct contact to their clientele is particularly important for them.

Employees

Years on the Market

Worldwide Subsidiaries

In their modern research facilities and laboratory centers they continuously develop new materials for their customers´ special requirements. It is their know-how and the flexibility and great willingness of their workforce that have made them successful for over 80 years as experts for friction lining technology.

Like their company - in accordance with DIN EN ISO 9001:2008 and IRIS - their linings have been frequently tested and certified.

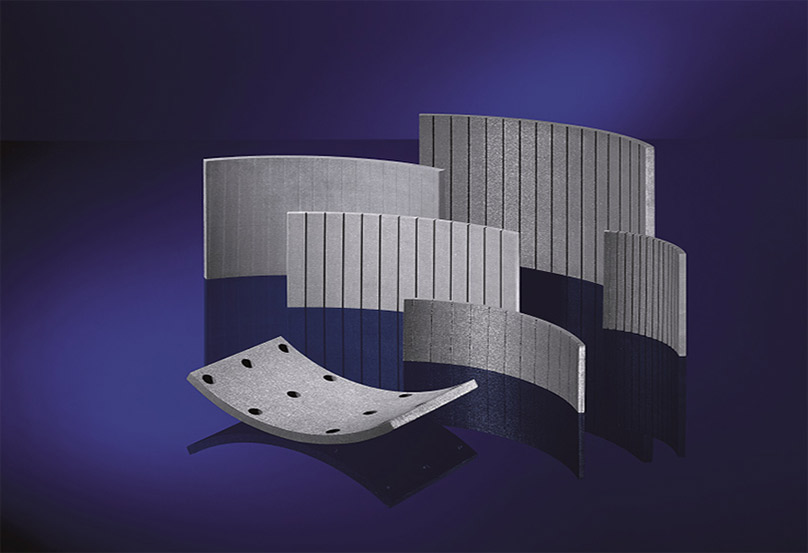

With the most modern automated production facilities they produce a variety of different, state-of-the-art brake and clutch lining variants, which are aligned with regard to shape, size, geometry and dimensions to the individual requirements of their customers.

For anchor winches BREMSKERL offers flexible woven rolled material custom-made, weatherproofed and reliable.

In addition, they produce high-quality semi-finished goods in the form of rolls, strips and plates in thicknesses of up to 80 mm.

BREMSKERL rolls can also be supplied with wire backing fabric and can be both riveted and bonded for the highest stresses.

Additional grooving ensures particularly high flexibility of the material for very different drum diameters. Through various types of processes, for example, milling, water jet and laser cutting, all semi-finished products can be further processed to the required dimensions in a great range of variants.

In addition, we regenerate and bond various carrier materials.

BREMSKERL materials are used successfully in all application fields globally. This is not a coincidence, because their materials guarantee high economic efficiency and unique product quality through particularly safe manufacturing processes.

In addition, their linings achieve optimum friction pairing in the shortest time.

Best performance values and high friction coefficient stability, even at high temperatures, are provided only by composites from BREMSKERL.

Brake bands and drum brake linings for

- Cranes

- Winches

- Forklifts

- Other Industrial Applications

BREMSKERL 5300 is an OE approved material for forklift drum brakes.

Ideal for brake and clutch applications requiring riveting instead of bonding: brake bands, forklifts, antique vehicles.

Industrial Flexible moulded and woven band; hot and cold pressed finished & semi-manufactured articles; e.g. rings, blocks, sheets. Railway Systems Brake Pads and Brake Blocks for transit and freight rail systems.

Commercial Vehicles Drum brake and disc brake pads for trucks, trailers, busses, cranes and specialty vehicles.