SKF Adjustable chocks and shims

SKF Adjustable chocks and shims

SKF Vibracon adjustable chocks

The chocking solution for rotating equipment

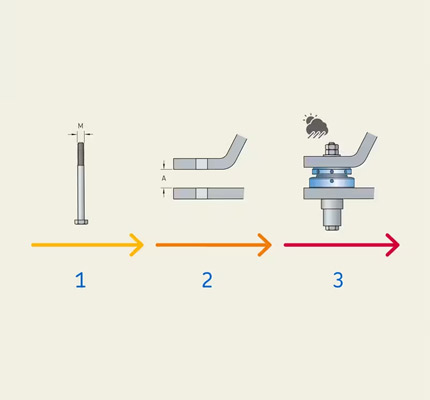

SKF Vibracon chocks are self-leveling and provide the option to reduce profile height. They allow easy, accurate mounting of all types of rotating equipment to base frames and either steel or concrete foundations. They accommodate the angular difference (up to 4°) between machine and mounting base without the need to machine the base or install epoxy resin chocks.

The chocks eliminate soft foot- and can lower the cost of equipment foundations – whether they are designed-in or retrofitted.

SKF Vibracon chocking solutions offer you the advantages of:

- A high load capacity

- A broad adjustment rangey

- An optimized load path through the product

- An optimized bolt/Vibracon combination

- Reduced chock height across the entire range

SKF Vibracon chocks can save costs and raise performance in many industries, including:

- Food & beverage

- Pulp & paper

- Oil & gas

- Marine & offshore

- Railways

- Power generation – including renewable energy

- Agriculture

- Clean room application

Typical SKF Vibracon applications are:

- Gas and diesel engines

- Compressors

- Electric motors

- Gearboxes

- Generators

- Pumps and fans

- Bearing housings

- Turbines

- Other critical rotating machinery

Catalogues/Downloads

Catalogues/Downloads

Εxplore our wide range of products

Rolling Bearings

Mounted bearings and housings

Super-precision bearings

Slewing bearings

Marine Bearings – ORKOT

Maintenance products & tools

Linear technology

Motion Plastics – IGUS

Lubrication systems & Pump systems

Sealing solutions

Power transmission solutions

Rod ends, spherical plain bearings

Couplings

Brake linings

Expansion joints

Shaft braking systems

Motors

Antivibration mountings

Bushings, thrust washers and strips