Control units and software

Control units and software

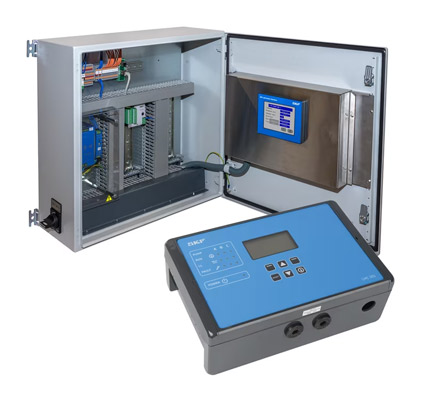

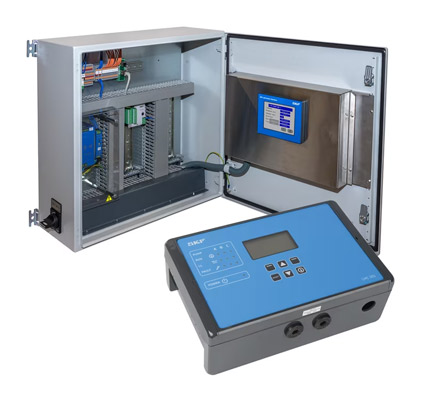

Control units and software for use in lubrication systems

Control units in total loss lubrication systems trigger the lubrication routine, regulate the duration of the idle time between two lubrication routines and evaluate system parameters. If faults occur, one or more output signals, or indicators are available to help the machine's operator take the appropriate action in regard to the machine or system. This protects the machine or system against severe damage.

In oil circulation systems, the machine's control unit usually assumes control of the centralized lubrication system. Devices are available to analyze the data from the system sensors. In normal or faulty operation of the centralized lubrication system, these devices make the output signals available for further analysis.

Remote control and monitoring software packages are available for both types of lubrication systems.

Monitoring values

- Lubrication routine

- Time

- Pressure

- Lubricant quantity

- Lubricant level

- Number of cycles (monitoring)

Applications

- Single-line lubrication systems

- Dual-line lubrication systems

- Progressive lubrication systems

- Multi-line lubrication systems

- Small oil circulation systems

- Oil and air lubrication systems

- Minimal quantity lubrication systems

Catalogues/Downloads

- SKF Maintenance and Lubrication Products

- SKF Single-line automatic lubrication systems

- SKF Dual-line automatic lubrication system

- SKF Multi-line automatic lubrication systems

- SKF Progressive automatic lubrication systems

- SKF Automatic oil circulation lubrication systems

- SKF Fittings and accessories for lubrication systems

Catalogues/Downloads

Εxplore our wide range of products

Rolling Bearings

Mounted bearings and housings

Super-precision bearings

Slewing bearings

Marine Bearings – ORKOT

Maintenance products & tools

Linear technology

Motion Plastics – IGUS

Lubrication systems & Pump systems

Sealing solutions

Power transmission solutions

Rod ends, spherical plain bearings

Couplings

Brake linings

Expansion joints

Shaft braking systems

Motors

Antivibration mountings

Bushings, thrust washers and strips