SKF Surface treated chocks

SKF Surface treated chocks

SKF Vibracon E-CSTR series

Chocks are often installed in demanding environments, including humid and salty climates – where enhanced corrosion protection is recommended. (It is worth noting that SKF Vibracon chocks were originally developed for marine applications.)

To satisfy this need, SKF has tested a range of protective solutions, resulting in its surface-treated chocks. Each part is individually surface treated, which helps to give the chocks a consistent quality and extended performance against corrosion.

The SKF Vibracon is available in different materials to meet the need of your application, even those in the harshest environments.

- Carbon steel E-CS series

- Surface treated carbon steel E-CSTR series

- Stainless steel E-SS series

- Surface treated alloy steel low profile ELP-ASTR series

SKF VIBRACON SELECTION TOOL

How to select the appropriate SKF Vibracon chock

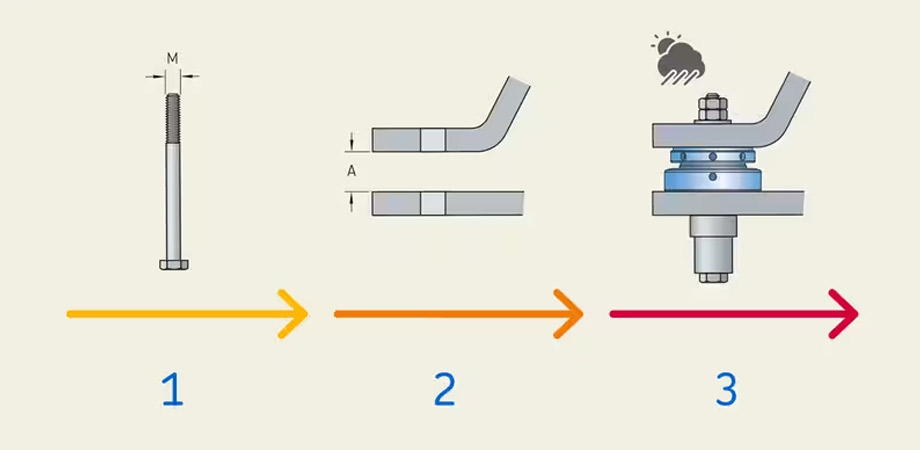

The Vibracon selection tool is an online calculation tool to determine the most suitable SKF Vibracon chock for your application in 3 simple steps:.1. Diameter of the foundation bolt (M) - 2. Available chocking height (A) - 3. Check environmental conditions

Catalogues/Downloads

Catalogues/Downloads

Related products

Related products

Εxplore our wide range of products

Rolling Bearings

Mounted bearings and housings

Super-precision bearings

Slewing bearings

Marine Bearings – ORKOT

Maintenance products & tools

Linear technology

Motion Plastics – IGUS

Lubrication systems & Pump systems

Sealing solutions

Power transmission solutions

Rod ends, spherical plain bearings

Couplings

Brake linings

Expansion joints

Shaft braking systems

Motors

Antivibration mountings

Bushings, thrust washers and strips