Chain lubrication on agricultural machines

Chain lubrication on agricultural machines

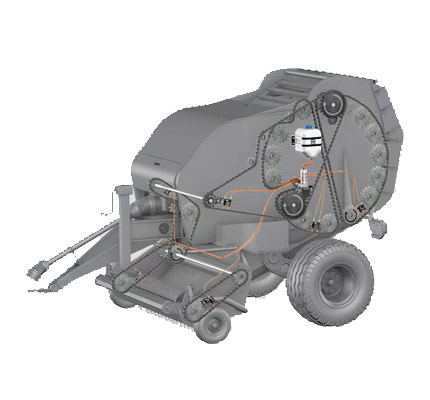

During harvesting season, farmers focus on the task at hand. They do not want distractions – such as whether their baling machine will last the duration of the harvest. By reducing chain wear, automatic lubrication systems lessen the chance of downtime. Compared to manual chain lubrication, continuous lubrication can deliver a five-fold increase in reliability and service life.

The harsh conditions during harvesting and baling, such as dust, moisture and vibration, continuously stress all machine elements, specifically the chains. Continuous lubrication is vital for chain life.

Automatic chain lubrication systems remove the need for manual lubrication. As well as freeing up time, this improves safety – as lubricating chains manually can be hazardous. In addition, the accuracy of automatic lubrication can help to reduce overall lubricant costs. The mechanically driven system is available as a pre-configured kit. It is easy to select and install – a cost-effective way of raising operational efficiency.

Recently launched

Reliable chain lubrication

The chain lubrication system OCL-M gives farmers confidence that machinery will run with maximum reliability.

EOP2

The Lincoln EOP2 is an electrically operated gear pump unit with reservoir for EOS (Electrical single-line Oil System) chain lubrication.

MPG 101

The combination of an oil (MOS/MOP 212) and a grease pump (MGP 101) results is a type of tandem pump for both oil and grease.

MOS / MOP

Mechanically driven oil lubrication pump for slow moving chains, pumps are connected directly to the chain.

Catalogues/Downloads

- SKF Maintenance and Lubrication Products

- SKF Single-line automatic lubrication systems

- SKF Dual-line automatic lubrication system

- SKF Multi-line automatic lubrication systems

- SKF Progressive automatic lubrication systems

- SKF Automatic oil circulation lubrication systems

- SKF Fittings and accessories for lubrication systems

Catalogues/Downloads

Εxplore our wide range of products

Rolling Bearings

Mounted bearings and housings

Super-precision bearings

Slewing bearings

Marine Bearings – ORKOT

Maintenance products & tools

Linear technology

Motion Plastics – IGUS

Lubrication systems & Pump systems

Sealing solutions

Power transmission solutions

Rod ends, spherical plain bearings

Couplings

Brake linings

Expansion joints

Shaft braking systems

Motors

Antivibration mountings

Bushings, thrust washers and strips