Minimal quantity lubrication units

Minimal quantity lubrication units

Minimal quantity lubrication units

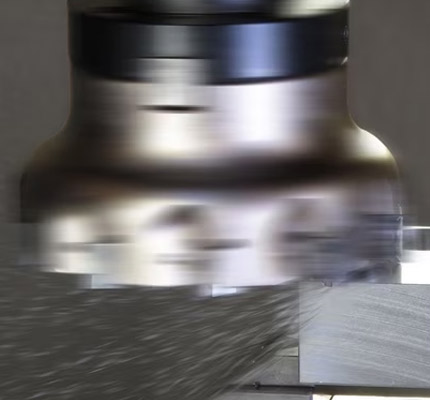

When performing cutting operations, minimal quantity lubrication (MQL) eliminates the need for complicated wet machining. The principle is simple - lubricant is applied to the tool’s cutting edge as an aerosol in the exact amount required. Using MQL, lubricant consumption is measured in millilitres per hour instead of litres per minute.

Alternating use of wet and dry machining on one machine is easy to implement with SKF LubriLean. In addition to integration in new machine tools, low-maintenance MQL devices can be used to retrofit most existing machinery.

Featuring SKF LubriLean and Vectolub, we offer a complete range of technology for both internal and external MQL. Internal MQL solutions transport the aerosol internally through the tool holder and tool, while external MQL solutions use external lines and nozzles to feed the aerosol.

On most advanced internal lubrication systems, the aerosol quantity can be set by your machine tool’s PLC – an efficient solution for machining and turning centres. When the tool shape or length is changed, there is no need for time-consuming readjustment of the nozzles to make the aerosol reach the lubrication point.

Differentiation criteria

- External or internal application

- Number of outlet ports

- Reservoir capacity

- Compressed air pressure

- Type of actuation

- Air consumption

Applications

- Drilling, milling, broaching, tapping, thread forming applications

- Machining centers

- Turning centers

- Special machines with one or more spindles

SUSTAINABILITY

Enough is enough

Minimum Quantity Lubrication is becoming increasingly popular in machining processes, as it is sustainable and environmentally friendly while improving productivity and cutting costs.

Catalogues/Downloads

- SKF and Lincoln automatic lubrication systems

- SKF LubriLean Minimal quantity lubrication improves ecological and economic efficiency

- SKF LubriLean Minimal Quantity Lubrication (MQL) for Dry Machining Processes

- SKF Product series DigitalSuper

- SKF VectoLub

- SKF Maintenance and Lubrication Products

- SKF Single-line automatic lubrication systems

- SKF Dual-line automatic lubrication system

- SKF Multi-line automatic lubrication systems

- SKF Progressive automatic lubrication systems

- SKF Automatic oil circulation lubrication systems

- SKF Fittings and accessories for lubrication systems

Catalogues/Downloads

Εxplore our wide range of products

Rolling Bearings

Mounted bearings and housings

Super-precision bearings

Slewing bearings

Marine Bearings – ORKOT

Maintenance products & tools

Linear technology

Motion Plastics – IGUS

Lubrication systems & Pump systems

Sealing solutions

Power transmission solutions

Rod ends, spherical plain bearings

Couplings

Brake linings

Expansion joints

Shaft braking systems

Motors

Antivibration mountings

Bushings, thrust washers and strips