Minimal quantity lubrication (MQL)

Minimal quantity lubrication (MQL)

For lubrication of high-speed cutting operations

Machine operators can reduce production costs significantly by using SKF minimal quantity lubrication systems (MQL). These systems provide longer tool life and improved production quality due to more precise surface machining.

Because MQL systems do not require cooling lubricant, the cost of that lubricant, its associated lubricant filters, preparation systems and disposal is eliminated. Also workpieces and chippings do not need to be cleaned.

Features & benefits

-Extends the service life of the cutting tool

- Increases productivity with higher cutting speed

- Reduces maintenance costs

- Enables better machining surface and quality

- Reduces energy consumption and CO2 emissions

Typical applications

- Milling

- Rolling

- Cutting

- Drilling

- Boring

- Forming

Minimal quantity lubrication systems

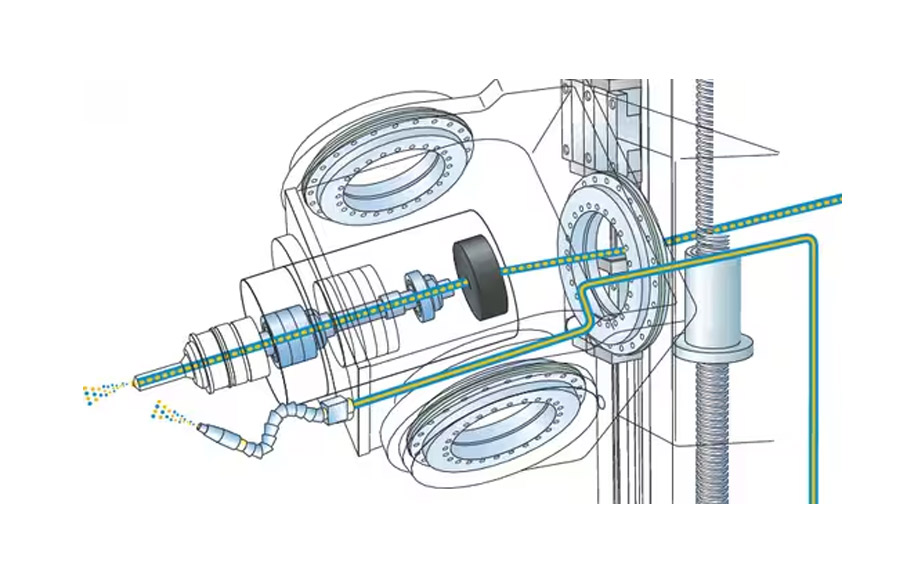

Lubricant is applied to the tool’s cutting edge as an aerosol. Using MQL, lubricant consumption is measured in millilitres per hour instead of litres per minute.

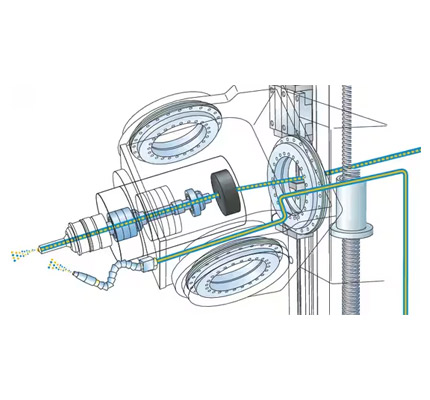

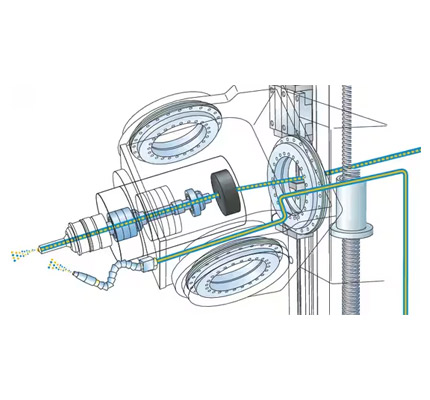

Description Internal MQL:

With the internal lubrication method, compressed air or the aerosol is applied through the spindle, the tool holder and the tool directly at the point between tool and workpiece.

Description External MQL:

With the external lubrication method, the aerosol is supplied to the lubrication point from the outside through nozzles. With the right expertise, machine tools that are not supplied with internal MQL, can be upgraded with SKF LubriLean external method.

SUSTAINABILITY

Enough is enough

Minimum Quantity Lubrication is becoming increasingly popular in machining processes, as it is sustainable and environmentally friendly while improving productivity and cutting costs.

Minimal quantity lubrication units

For internal and external MQL. SKF LubriLean units and SKF Vectolub units.

Catalogues/Downloads

- SKF and Lincoln automatic lubrication systems

- SKF LubriLean Minimal Quantity Lubrication (MQL) for Dry Machining Processes

- SKF Product series DigitalSuper

- SKF VectoLub

- SKF Maintenance and Lubrication Products

- SKF Single-line automatic lubrication systems

- SKF Dual-line automatic lubrication system

- SKF Multi-line automatic lubrication systems

- SKF Progressive automatic lubrication systems

- SKF Automatic oil circulation lubrication systems

- SKF Fittings and accessories for lubrication systems

Catalogues/Downloads

Εxplore our wide range of products

Rolling Bearings

Mounted bearings and housings

Super-precision bearings

Slewing bearings

Marine Bearings – ORKOT

Maintenance products & tools

Linear technology

Motion Plastics – IGUS

Lubrication systems & Pump systems

Sealing solutions

Power transmission solutions

Rod ends, spherical plain bearings

Couplings

Brake linings

Expansion joints

Shaft braking systems

Motors

Antivibration mountings

Bushings, thrust washers and strips