igus® | Reliable, Long-Term Energy Solutions for STS Cranes

igus® | Reliable, Long-Term Energy Solutions for STS Cranes

Reliable, Long-Term Energy Solutions for STS Cranes

Whether it's a monobeam, double trolley, gooseneck, shuttle boom, or lattice girder crane, efficient ship-to-shore

operations rely on high-performance energy supply systems.

These large-scale cranes demand maximum reliability and functionality,

even under extreme mechanical stress, harsh weather, and corrosive environments.

To ensure uninterrupted loading and unloading processes, operators must have complete confidence in both the energy chains and cables.

That’s why we offer a comprehensive range of durable energy chain systems, combined with smart sensor technology for real-time

condition monitoring and predictive maintenance — helping our customers maintain peak performance and avoid costly downtime.

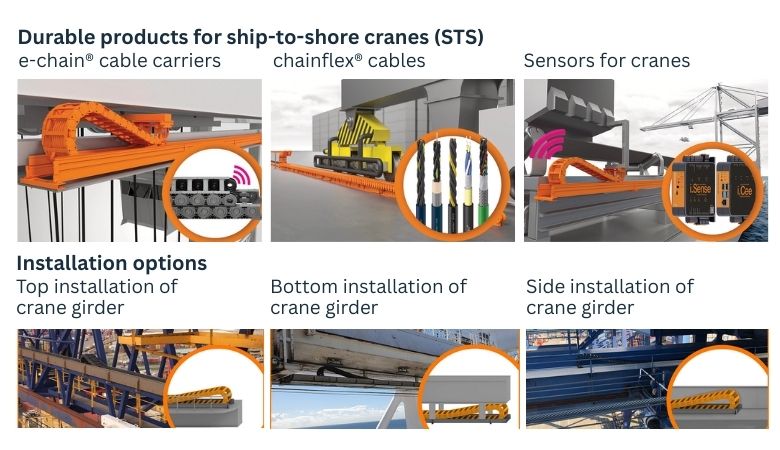

Versatile Installation Options for Energy Chains on STS Cranes

Ready for any scenario. Depending on the specific application and crane design, energy chain systems can be

installed in a variety of configurations to suit operational needs.

While mounting on top of the crane girder is the standard approach, side-mounted installations offer

enhanced protection against strong crosswinds.

Alternatively, positioning the energy chain underneath the girder provides maximum shielding from snow, rain, and ice.

Whatever the environmental or structural requirements, we offer tailored energy chain solutions and mounting options to

ensure optimal performance and durability in every condition.

Just watch this video: igus - energy chain for its new STS cranes

To find out more about intelligent, reliable smart plastics, please ask our igus expert team or visit our website igus – motion plastics